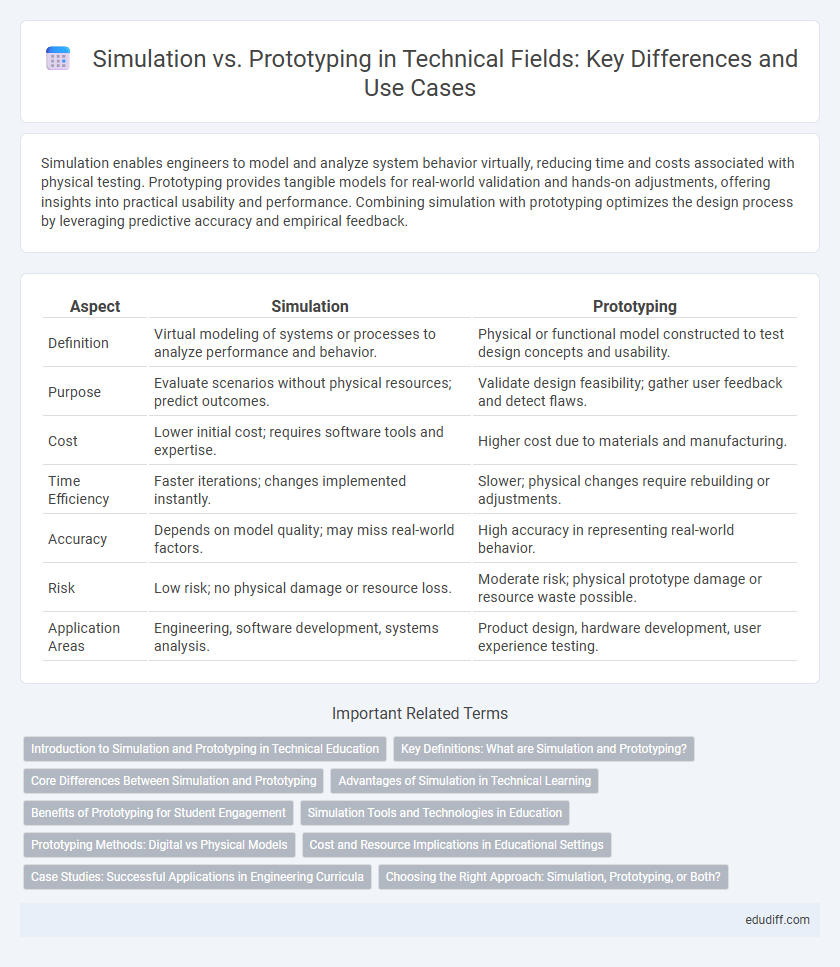

Simulation enables engineers to model and analyze system behavior virtually, reducing time and costs associated with physical testing. Prototyping provides tangible models for real-world validation and hands-on adjustments, offering insights into practical usability and performance. Combining simulation with prototyping optimizes the design process by leveraging predictive accuracy and empirical feedback.

Table of Comparison

| Aspect | Simulation | Prototyping |

|---|---|---|

| Definition | Virtual modeling of systems or processes to analyze performance and behavior. | Physical or functional model constructed to test design concepts and usability. |

| Purpose | Evaluate scenarios without physical resources; predict outcomes. | Validate design feasibility; gather user feedback and detect flaws. |

| Cost | Lower initial cost; requires software tools and expertise. | Higher cost due to materials and manufacturing. |

| Time Efficiency | Faster iterations; changes implemented instantly. | Slower; physical changes require rebuilding or adjustments. |

| Accuracy | Depends on model quality; may miss real-world factors. | High accuracy in representing real-world behavior. |

| Risk | Low risk; no physical damage or resource loss. | Moderate risk; physical prototype damage or resource waste possible. |

| Application Areas | Engineering, software development, systems analysis. | Product design, hardware development, user experience testing. |

Introduction to Simulation and Prototyping in Technical Education

Simulation in technical education enables students to model complex systems virtually, facilitating risk-free experimentation and deeper understanding of theoretical concepts. Prototyping complements this by allowing hands-on creation of physical models, enhancing practical skills and iterative design thinking. Both methods are crucial for bridging the gap between conceptual knowledge and real-world application in engineering and technology disciplines.

Key Definitions: What are Simulation and Prototyping?

Simulation is a computational technique that replicates real-world processes or systems to analyze behavior under various conditions without physical execution. Prototyping involves creating a tangible model or version of a product to validate design concepts, functionality, and usability through physical interaction. Both methods serve critical roles in engineering and product development by reducing risks and enhancing design accuracy before final production.

Core Differences Between Simulation and Prototyping

Simulation uses virtual models and computer algorithms to replicate system behavior under various conditions, enabling cost-effective testing and rapid iteration. Prototyping involves building physical or functional models to evaluate real-world performance, user interaction, and design feasibility. Key differences lie in the abstraction level, with simulation offering intangible virtual analysis and prototyping providing tangible, hands-on validation.

Advantages of Simulation in Technical Learning

Simulation offers unparalleled advantages in technical learning by enabling risk-free experimentation with complex systems and scenarios that would be costly or dangerous to replicate physically. It facilitates accelerated skill acquisition through immediate feedback and iterative practice, enhancing understanding of system behaviors and failure modes without material constraints. Furthermore, simulation supports scalability and accessibility, allowing learners to engage with realistic environments anytime and anywhere, thereby optimizing training efficiency and resource utilization.

Benefits of Prototyping for Student Engagement

Prototyping enhances student engagement by providing hands-on experience that bridges theoretical knowledge and practical application. Interactive models allow students to visualize complex systems, fostering deeper understanding and retention of technical concepts. This experiential learning approach cultivates creativity, problem-solving skills, and active participation, which are often limited in purely simulation-based methods.

Simulation Tools and Technologies in Education

Simulation tools in education enable immersive, risk-free learning experiences by replicating real-world systems through advanced software platforms such as MATLAB, Simulink, and ANSYS. These technologies enhance comprehension of complex concepts in engineering, physics, and healthcare by allowing students to manipulate variables and observe outcomes dynamically. Integrating virtual labs and interactive 3D models accelerates skill acquisition and prepares learners for practical scenarios without the costs and constraints associated with physical prototyping.

Prototyping Methods: Digital vs Physical Models

Prototyping methods encompass digital and physical models, each serving distinct purposes in product development. Digital models enable rapid iterations and virtual testing through software tools, reducing costs and development time. Physical prototypes provide tangible feedback and usability insights, essential for assessing ergonomics and real-world performance before final production.

Cost and Resource Implications in Educational Settings

Simulation in educational settings significantly reduces costs by minimizing the need for physical materials and equipment, allowing repeated practice without wear or replacement expenses. Prototyping, while more resource-intensive due to the requirement of physical models and materials, offers hands-on experience that can enhance learning outcomes but demands higher investment in supplies and space. Balancing these approaches optimizes resource allocation by leveraging cost-effective simulations for foundational skills and reserving prototyping for advanced, tactile learning scenarios.

Case Studies: Successful Applications in Engineering Curricula

Case studies in engineering curricula demonstrate that simulation enhances conceptual understanding through virtual experimentation, enabling cost-effective and risk-free testing of complex systems. Prototyping offers tangible insights by allowing hands-on construction and iterative refinement, which reinforces practical skills and real-world problem-solving. Integrating both methods fosters a comprehensive learning experience, balancing theoretical analysis with experiential validation.

Choosing the Right Approach: Simulation, Prototyping, or Both?

Selecting between simulation and prototyping depends on project goals, resources, and development phase; simulation excels in early-stage design validation by providing cost-effective virtual testing of system behavior under various conditions. Prototyping offers tactile evaluation and user feedback, essential for refining physical interactions and detecting design flaws not apparent in simulations. Combining both methods leverages the predictive power of simulations and the practical insights of prototypes, optimizing product development efficiency and accuracy.

Simulation vs Prototyping Infographic

edudiff.com

edudiff.com