PLC programming is specialized for industrial automation, utilizing ladder logic or function block diagrams to control machinery with high reliability and real-time response. Embedded systems programming involves developing software for microcontrollers or processors integrated into various devices, requiring expertise in low-level coding and hardware interaction. Understanding the distinct environments and constraints of PLCs and embedded systems ensures optimized performance and system stability in their respective applications.

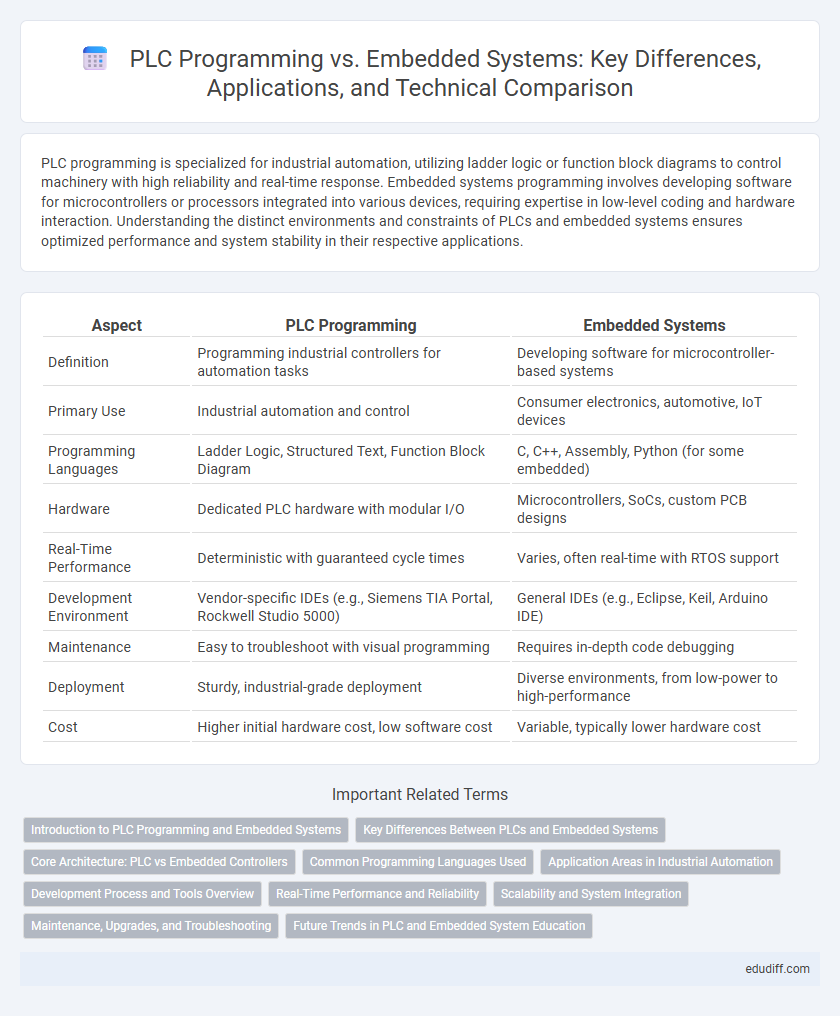

Table of Comparison

| Aspect | PLC Programming | Embedded Systems |

|---|---|---|

| Definition | Programming industrial controllers for automation tasks | Developing software for microcontroller-based systems |

| Primary Use | Industrial automation and control | Consumer electronics, automotive, IoT devices |

| Programming Languages | Ladder Logic, Structured Text, Function Block Diagram | C, C++, Assembly, Python (for some embedded) |

| Hardware | Dedicated PLC hardware with modular I/O | Microcontrollers, SoCs, custom PCB designs |

| Real-Time Performance | Deterministic with guaranteed cycle times | Varies, often real-time with RTOS support |

| Development Environment | Vendor-specific IDEs (e.g., Siemens TIA Portal, Rockwell Studio 5000) | General IDEs (e.g., Eclipse, Keil, Arduino IDE) |

| Maintenance | Easy to troubleshoot with visual programming | Requires in-depth code debugging |

| Deployment | Sturdy, industrial-grade deployment | Diverse environments, from low-power to high-performance |

| Cost | Higher initial hardware cost, low software cost | Variable, typically lower hardware cost |

Introduction to PLC Programming and Embedded Systems

PLC programming involves designing and coding logic sequences to automate industrial machinery using ladder logic or functional block diagrams. Embedded systems programming focuses on creating firmware for microcontrollers to control specific hardware functions in real time. Both domains require precise timing and resource management but differ in application scope and programming paradigms.

Key Differences Between PLCs and Embedded Systems

PLCs (Programmable Logic Controllers) are industrial computers designed for real-time automation and control in manufacturing processes, featuring robust I/O handling and simplified programming languages like ladder logic. Embedded systems are specialized computing units integrated within devices, optimized for specific functionalities with more complex programming environments, often coded in C or assembly. Key differences include PLCs' emphasis on reliability and ease of maintenance in harsh environments versus embedded systems' focus on compactness, power efficiency, and versatility for consumer electronics and custom applications.

Core Architecture: PLC vs Embedded Controllers

PLC programming relies on a standardized, modular architecture designed for industrial automation with ruggedness and real-time deterministic control, using ladder logic or function block diagrams. Embedded controllers feature a highly customizable architecture focused on low-level hardware integration and resource efficiency, often programmed in C/C++ for specific application requirements. The core difference lies in PLCs emphasizing reliability and ease of use in harsh environments, while embedded systems prioritize flexibility and optimization for diverse hardware platforms.

Common Programming Languages Used

PLC programming predominantly uses Ladder Logic, Structured Text, and Function Block Diagram languages standardized under IEC 61131-3, optimizing automation and industrial control systems. Embedded systems rely heavily on C and C++ for their efficient low-level hardware manipulation and real-time performance capabilities. Both domains sometimes utilize Python and Assembly language for specialized tasks or rapid prototyping, reflecting diverse language ecosystems tailored to system requirements.

Application Areas in Industrial Automation

PLC programming is extensively used in industrial automation for controlling manufacturing processes, assembly lines, and robotic devices due to its robustness and real-time operation capabilities. Embedded systems are integral in applications requiring customized, compact solutions such as sensor integration, motor control, and data acquisition within automated machinery. Both technologies play crucial roles in smart factory environments, enhancing efficiency through precise control and monitoring across varied industrial automation tasks.

Development Process and Tools Overview

PLC programming utilizes specialized software like Siemens TIA Portal and Rockwell Studio 5000, featuring ladder logic and function block diagrams tailored for industrial automation. Embedded systems development involves C/C++ programming with tools such as Keil, IAR Embedded Workbench, and integrated development environments (IDEs) supporting real-time operating systems, focusing on low-level hardware interaction. The development process for PLCs emphasizes reliability and ease of maintenance in controlled environments, while embedded systems require extensive hardware-software integration and debugging across diverse platforms.

Real-Time Performance and Reliability

PLC programming is designed for robust real-time performance in industrial automation, ensuring deterministic task execution with minimal latency under harsh conditions. Embedded systems offer greater flexibility and customization but may require additional optimization to meet strict real-time constraints and maintain reliability. Reliability in PLCs is enhanced by standardized hardware and fail-safe mechanisms, while embedded systems depend heavily on software quality and hardware selection to achieve comparable uptime.

Scalability and System Integration

PLC programming offers high scalability and seamless integration within industrial automation systems through standardized protocols like Modbus and Ethernet/IP, facilitating easy expansion and interoperability. Embedded systems, while highly customizable and efficient for specific applications, often require more complex integration efforts and tailored scalability solutions due to proprietary hardware and software constraints. Effective system integration in PLCs relies on modular hardware and software libraries, whereas embedded systems demand in-depth firmware development and cross-platform communication strategies for scalable deployment.

Maintenance, Upgrades, and Troubleshooting

PLC programming offers straightforward maintenance with standardized ladder logic, enabling quick troubleshooting and minimal downtime in industrial automation environments. Embedded systems require specialized knowledge for upgrades and debugging due to tightly integrated hardware and software architectures, often complicating maintenance processes. Efficient troubleshooting in embedded systems demands deep firmware analysis and hardware diagnostics, whereas PLCs benefit from modular components and widely supported programming interfaces.

Future Trends in PLC and Embedded System Education

Future trends in PLC programming and embedded system education emphasize integrating advanced AI-driven diagnostics and IoT connectivity to meet evolving industrial automation demands. Curricula increasingly incorporate real-time data analytics, cybersecurity protocols, and hands-on training with digital twin simulations. These developments prepare students for smart manufacturing environments and edge computing applications.

PLC Programming vs Embedded Systems Infographic

edudiff.com

edudiff.com