A 3D printing workshop excels in rapid prototyping through additive manufacturing, enabling complex geometries with minimal material waste. CNC machining labs offer precise subtractive fabrication, ideal for metal and hard materials requiring tight tolerances. Choosing between the two depends on project requirements such as material type, dimensional accuracy, and production speed.

Table of Comparison

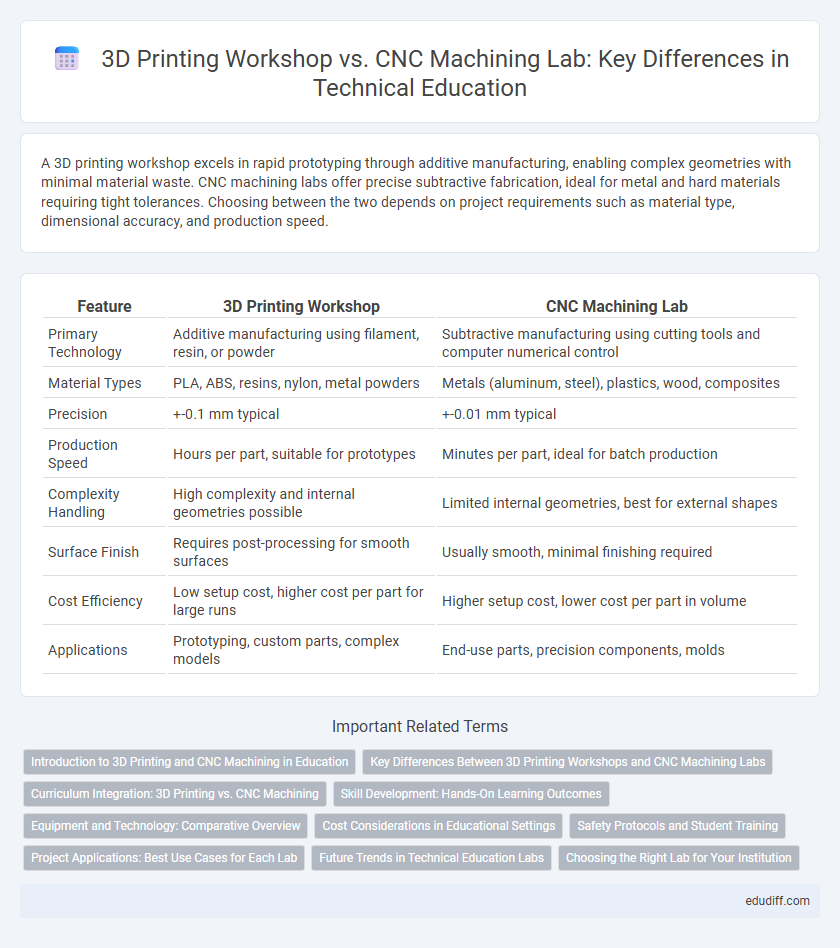

| Feature | 3D Printing Workshop | CNC Machining Lab |

|---|---|---|

| Primary Technology | Additive manufacturing using filament, resin, or powder | Subtractive manufacturing using cutting tools and computer numerical control |

| Material Types | PLA, ABS, resins, nylon, metal powders | Metals (aluminum, steel), plastics, wood, composites |

| Precision | +-0.1 mm typical | +-0.01 mm typical |

| Production Speed | Hours per part, suitable for prototypes | Minutes per part, ideal for batch production |

| Complexity Handling | High complexity and internal geometries possible | Limited internal geometries, best for external shapes |

| Surface Finish | Requires post-processing for smooth surfaces | Usually smooth, minimal finishing required |

| Cost Efficiency | Low setup cost, higher cost per part for large runs | Higher setup cost, lower cost per part in volume |

| Applications | Prototyping, custom parts, complex models | End-use parts, precision components, molds |

Introduction to 3D Printing and CNC Machining in Education

3D printing introduces students to additive manufacturing by creating objects layer-by-layer from digital models, fostering innovation and rapid prototyping skills. CNC machining provides hands-on experience with subtractive manufacturing processes, using computer-controlled tools to precisely shape materials for engineering applications. Integrating both technologies in education enhances students' understanding of manufacturing workflows and equips them with essential skills for modern industry demands.

Key Differences Between 3D Printing Workshops and CNC Machining Labs

3D printing workshops utilize additive manufacturing techniques, building objects layer by layer from materials like plastics and resins, enabling complex geometries and rapid prototyping. CNC machining labs rely on subtractive processes, cutting away material from solid blocks of metal or plastic with high precision for parts requiring tight tolerances and superior surface finishes. Key differences include production speed, material types, cost efficiency for low versus high volume runs, and design flexibility inherent to each manufacturing method.

Curriculum Integration: 3D Printing vs. CNC Machining

Curriculum integration of 3D printing emphasizes rapid prototyping, design iteration, and material innovation, enabling students to explore complex geometries with additive manufacturing techniques. CNC machining labs focus on precision, subtractive processes, and material removal strategies, reinforcing skills in tool path programming and machine operation. Both methodologies complement engineering education by providing hands-on experience with digital fabrication technologies vital for modern manufacturing workflows.

Skill Development: Hands-On Learning Outcomes

3D printing workshops enhance skill development by enabling hands-on experience with additive manufacturing techniques, fostering creativity in digital modeling and precision in layer-by-layer construction. CNC machining labs offer practical learning through subtractive manufacturing processes, improving skills in computer-aided design (CAD), tool programming, and material removal accuracy. Both environments develop critical problem-solving abilities and technical proficiency essential for advanced manufacturing careers.

Equipment and Technology: Comparative Overview

3D printing workshops utilize additive manufacturing technologies such as FDM, SLA, and SLS printers to build objects layer by layer from digital models, enabling complex geometries with minimal material waste. CNC machining labs employ subtractive processes using computer-controlled mills, lathes, and routers to cut and shape materials from solid blocks, offering high precision and surface finish suitable for metal and hard plastic parts. Both setups integrate CAD/CAM software for design and toolpath programming but differ fundamentally in fabrication approaches, equipment specificity, and material capabilities.

Cost Considerations in Educational Settings

3D printing workshops typically offer lower initial equipment costs and reduced material waste compared to CNC machining labs, making them more accessible for educational institutions with limited budgets. CNC machining labs require significant investment in machinery, maintenance, and safety protocols, which can increase operational expenses. However, CNC machines provide higher precision and durability, often justifying the higher upfront and ongoing costs for advanced technical training programs.

Safety Protocols and Student Training

Strict adherence to safety protocols in both 3D printing workshops and CNC machining labs is essential to prevent accidents and ensure a secure learning environment. Students receive comprehensive training emphasizing proper equipment handling, hazard recognition, and emergency procedures tailored to each technology's unique risks. Regular safety audits and hands-on simulations reinforce best practices, fostering a culture of responsibility and operational excellence within technical education settings.

Project Applications: Best Use Cases for Each Lab

3D printing workshops excel in rapid prototyping, custom product development, and creating complex geometries with minimal material waste, making them ideal for design iteration and small-batch production. CNC machining labs are best suited for high-precision manufacturing, working with metal and hard plastics, and producing durable parts for aerospace, automotive, and industrial applications. Combining 3D printing with CNC machining enhances project versatility by leveraging additive manufacturing for complex shapes and subtractive processes for fine finishing and structural integrity.

Future Trends in Technical Education Labs

Emerging trends in technical education labs emphasize integrating 3D printing workshops with CNC machining labs to foster advanced additive and subtractive manufacturing skills among students. Increased adoption of hybrid labs equipped with multi-material 3D printers and multi-axis CNC machines supports hands-on learning aligned with Industry 4.0 requirements. Future-focused curriculum developments prioritize real-time simulation software and AI-driven tool path optimization to enhance precision and efficiency in prototyping and manufacturing training.

Choosing the Right Lab for Your Institution

Selecting between a 3D printing workshop and a CNC machining lab depends on your institution's project requirements and educational goals. 3D printing excels in rapid prototyping and complex geometries with additive manufacturing, while CNC machining offers precision and durability through subtractive manufacturing processes. Evaluate factors such as material compatibility, production volume, and skill development to align the lab choice with your curriculum and research needs.

3D Printing Workshop vs CNC Machining Lab Infographic

edudiff.com

edudiff.com